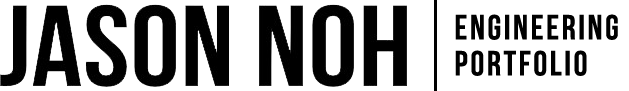

▲ Figure 1 – Pneumatic piston cylinder

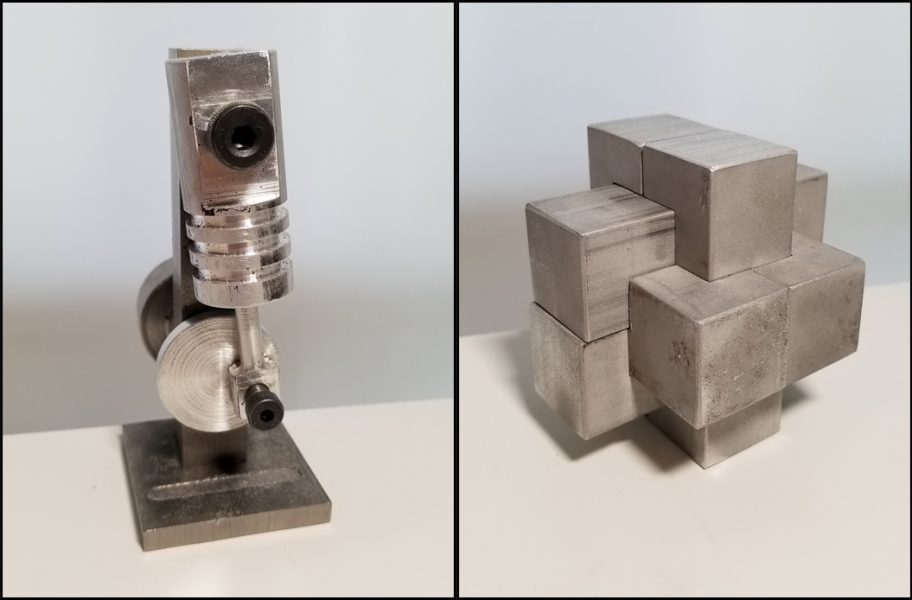

▲ Figure 2 – 3D puzzle

Creating something from scratch has always fascinated me, but is a skill I felt I needed more development. So, I took part in two voluntary courses offered jointly by University of Toronto and George Brown College that is designed for students to receive hands-on training for metal machining.

During the first course called Basic Machining, I was tasked on building a pneumatic piston cylinder out of solid aluminum blocks (Figure 1). The objective was to learn and practice machine shop safety, learn how to use a lathe, mill, and drill press, understand how to read engineering drawings in order to cut and mill properly, and learn how to utilize different measuring devices to ensure a function piston.

Figure 3 – Exploded engineering drawing of the pneumatic piston cylinder assembly

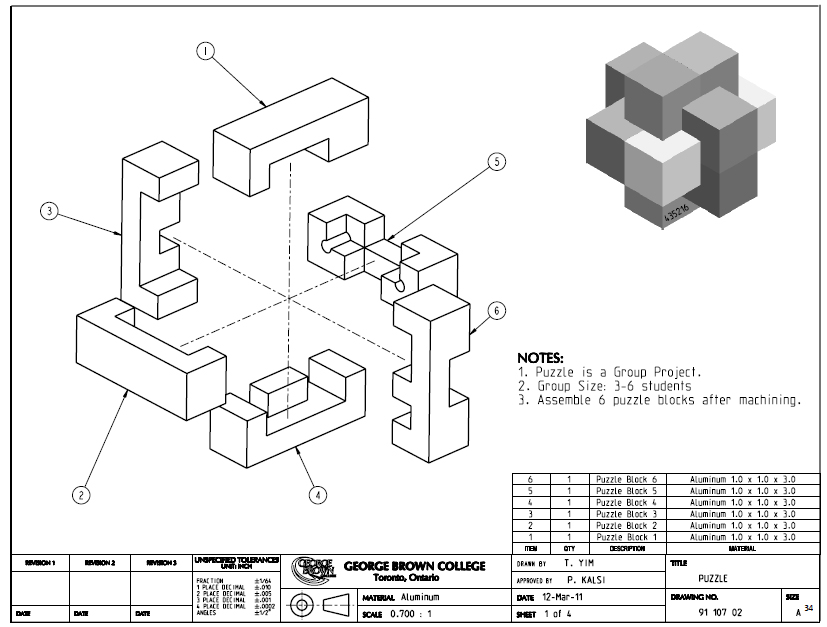

Figure 4 – Engineering drawing of the 3D puzzle assembly

The second more advanced course tasked us to create an aluminum 3D puzzle (Figure 2) out of solid blocks. In order for the puzzle to fit correctly, tolerances were smaller. This meant I had to measure parts more precisely than before, read the engineering drawings more carefully, and utilize the milling machine with higher precision. Furthermore, more problem solving skills had to be applied in order for the puzzle to fit and slide correctly.