2021 – 2022

At Form Technologies, I worked as a Tooling Excellence Engineer for its subsidiary company, Dynacast. I was the project lead in designing and upgrading the tooling repair and preventative maintenance program by utilizing lean six sigma tools and working closely with operational excellence and tooling leaders.

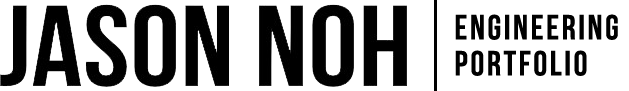

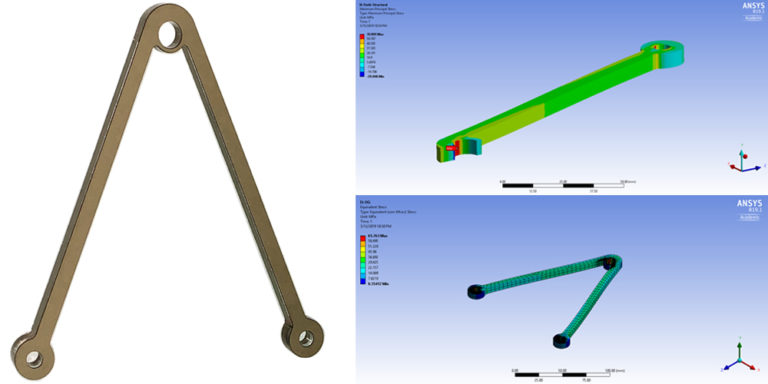

By performing finite element analysis in ANSYS, the strength-to-weight ratio of a PMMA acrylic part was increased by 5 times in a 3-point tensile test whilst reducing its mass down by more than 90%.

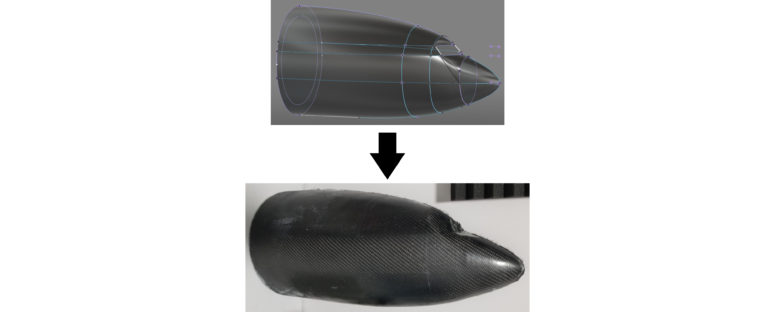

Let’s build a GIANT 2 meter long remote controlled airplane modelled after one of the most popular airliners in the world – the Boeing 737-800! This is part 1 of the series where I go over the design and CAD modeling process of the airliner.

July 2019 – August 2020

At Toyota Canada, I worked as a quality engineering intern. My role was to carry out root cause analysis on accessory quality concerns, develop countermeasures and standard operating procedures, engage in product evaluations, review drawings and quality control reports, and analyze and process warranty claims.

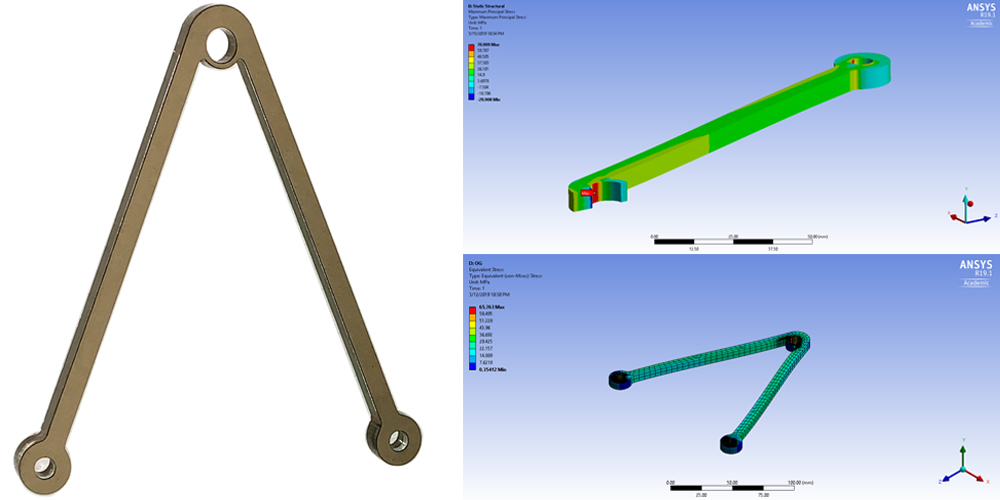

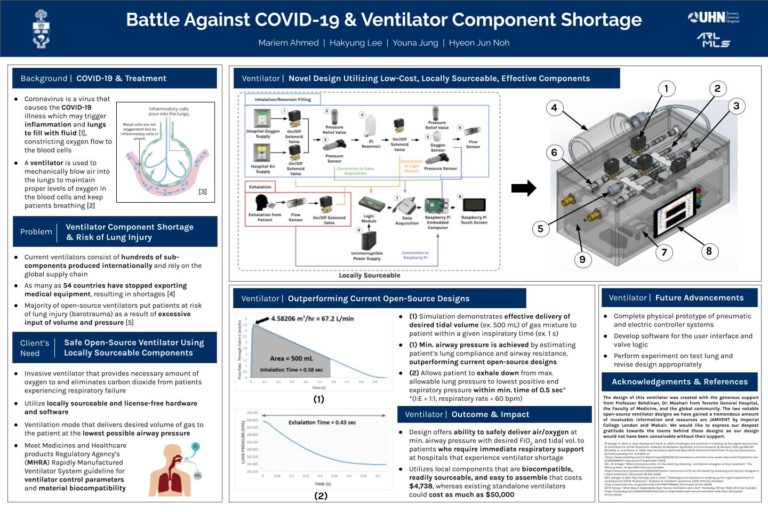

My 4th year Capstone team and I have researched and developed a safe open-source PRVC ventilator under the supervision of Prof. Behdinan and Dr. Mashari that adheres to MHRA standards using locally sourceable pneumatic components and logic controller for our client, Toronto General Hospital.

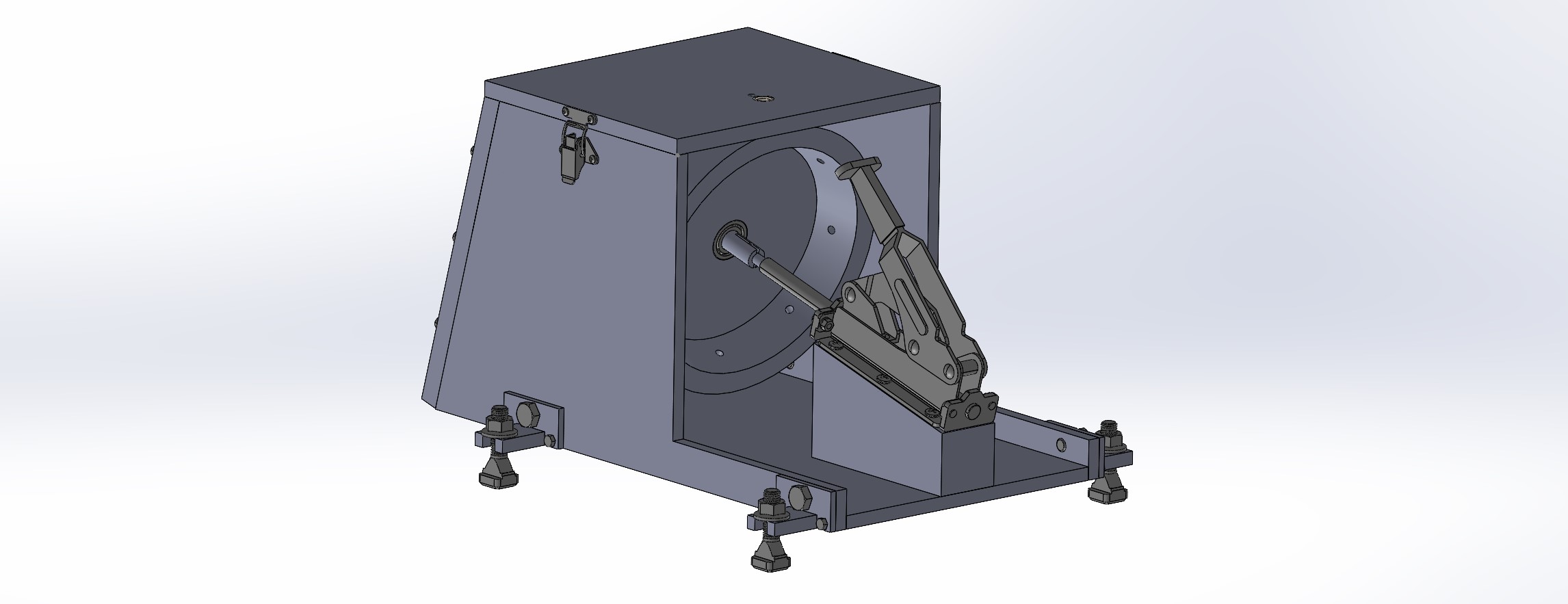

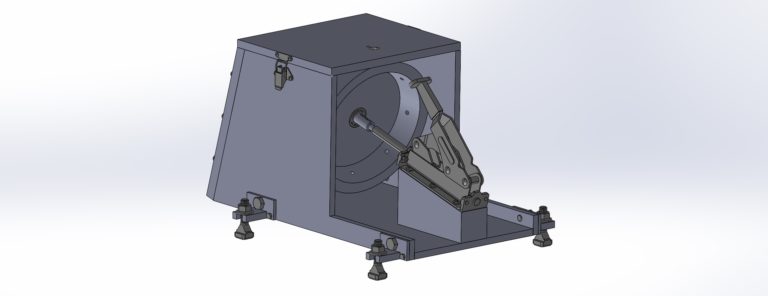

In a Design Optimization course, I designed a jig/fixture that assists in the fabrication of precisely located holes on a cone clutch utilizing GD&T controls, fits and allowances, and tolerance stack-up analysis. It was optimized to provide operator a straightforward method of loading parts and indexing.

About Me

Hi, I’m Jason! I am a mechanical engineering graduate from the University of Toronto and an engineer-in-training (EIT). I have three years of work experience (one year post-grad experience) working at companies like Toyota and Form Technologies where I gained experience in developing and evaluating new products & systems, manufacturing, and applying continuous improvement. I am passionate about the automotive and aerospace industry.

I’m always looking for new opportunities to learn and grow. You can reach me by email or LinkedIn!

Education

University of Toronto

Spring 2021

Bachelor of Applied Science | Mechanical Engineering with Honours

Minor in Engineering Business

- Professional Experience Year: Summer 2019 – Summer 2020

- Relevant Coursework

- MIE540 Product Design

- MIE506 MEMS Design & Microfabrication

- MIE442 Machine Design

- MIE441 Design Optimization

- MIE422 Automated Manufacturing

- ECE421 Introduction to Machine Learning

- Extracurriculars

- Korean Engineering Students’ Association (Executive Member)

- Da Vinci Engineering Enrichment Program Summer Academy

- UofT Formula Racing (Chassis Team)

Tooling Excellence Engineer at Form Technologies

2021 – 2022

At Form Technologies, I worked as a Tooling Excellence Engineer for its subsidiary company, Dynacast. I was the project lead in designing and upgrading the tooling repair and preventative maintenance program by utilizing lean six sigma tools and working closely with operational excellence and tooling leaders.

Toyota Canada Internship

July 2019 – August 2020

At Toyota Canada, I worked as a quality engineering intern. My role was to carry out root cause analysis on accessory quality concerns, develop countermeasures and standard operating procedures, engage in product evaluations, review drawings and quality control reports, and analyze and process warranty claims.

Internship at Dae Young Chemical

Summer 2016

Over the summer break of 2016, I worked as an intern at a Korean chemical company, Dae Young Chemical, that specializes in creating Teflon, ceramic, and paint coatings. I was there to learn the ins-and-outs of that part of the chemical industry: from the research and development process, all the way to the packaging and shipment.

Tooling Excellence Engineer at Form Technologies

2021 – 2022

At Form Technologies, I worked as a Tooling Excellence Engineer for its subsidiary company, Dynacast. I was the project lead in designing and upgrading the tooling repair and preventative maintenance program by utilizing lean six sigma tools and working closely with operational excellence and tooling leaders.

Toyota Canada Internship

July 2019 – August 2020

At Toyota Canada, I worked as a quality engineering intern. My role was to carry out root cause analysis on accessory quality concerns, develop countermeasures and standard operating procedures, engage in product evaluations, review drawings and quality control reports, and analyze and process warranty claims.

Internship at Dae Young Chemical

Summer 2016

Over the summer break of 2016, I worked as an intern at a Korean chemical company, Dae Young Chemical, that specializes in creating Teflon, ceramic, and paint coatings. I was there to learn the ins-and-outs of that part of the chemical industry: from the research and development process, all the way to the packaging and shipment.

Lightweight Yet Strong – Optimizing Strength-to-Weight Ratio in ANSYS

Building a Carbon Fiber RC Plane (737) – Designing & CAD Modeling

Capstone Project: Open-Source COVID-19 Ventilator

GD&T Design Project: Jig & Fixture

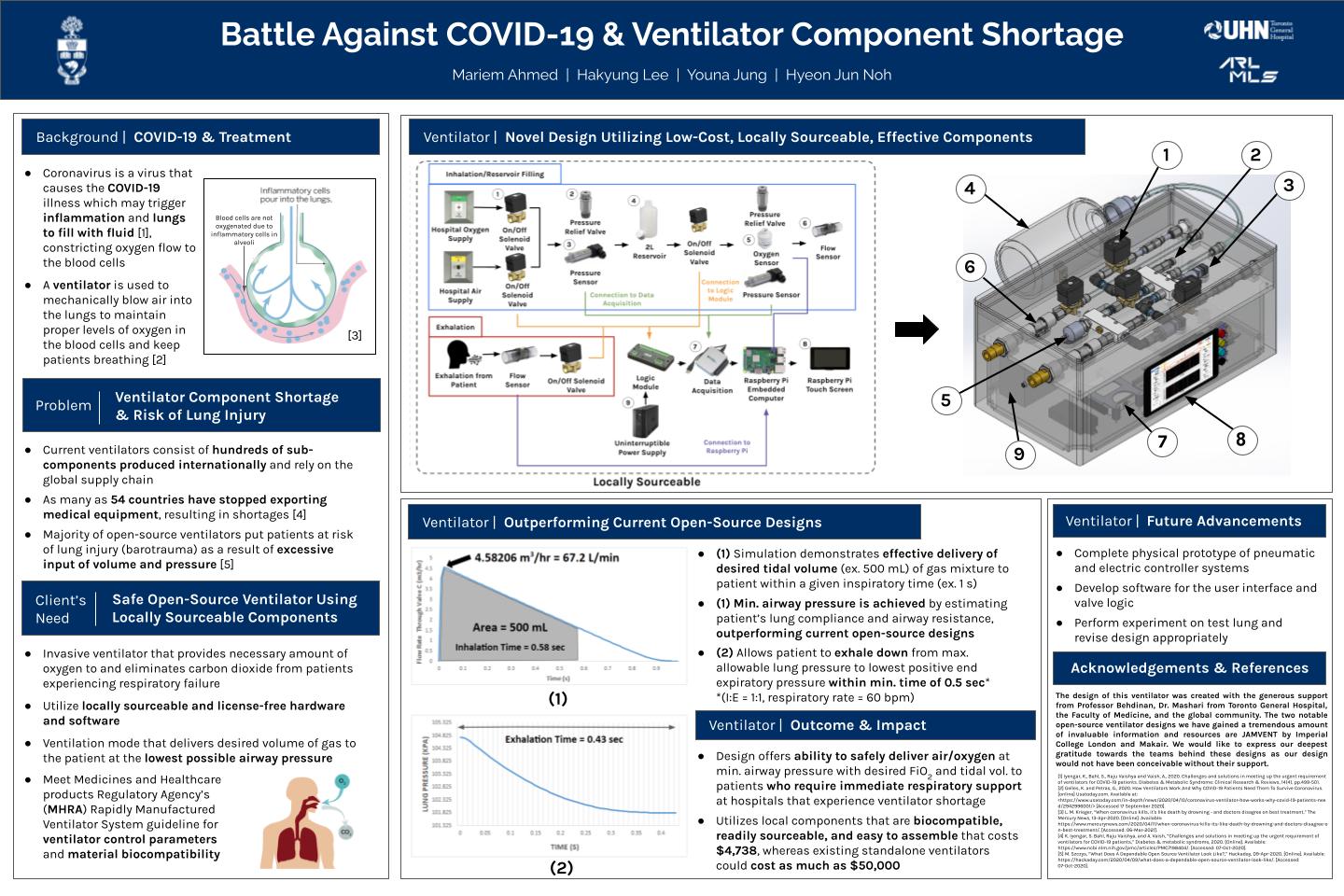

Blue Sky Solar Racing – Redesigning the Top Aero Body Hinge Mechanism

Building a Carbon Fiber RC Plane (737) – Turning Digital Design into Reality

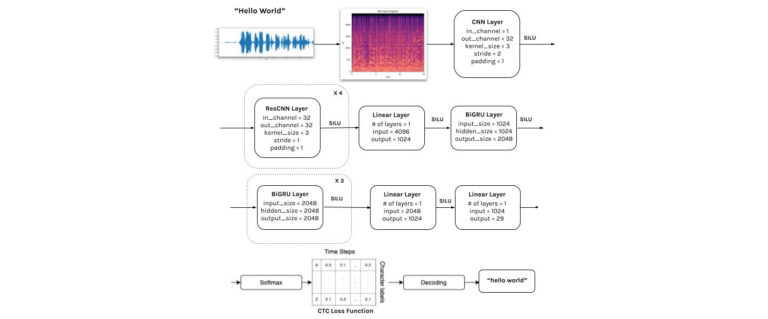

Speech-to-Text AI Program

Design Project: Shopping Cart

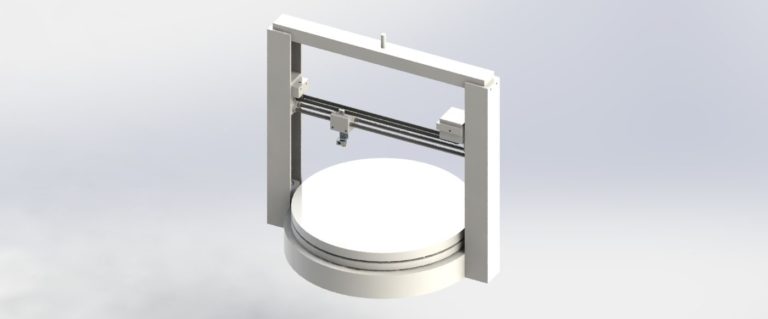

3D Printer Project

Skills & Certificates